2020-10-28 12:48:30

Where are Pirelli tyres made?

Pirelli in Russia

NOT ONLY PREMIUM

Pirelli products are primarily associated with the premium segment. This applies both to tyres going to the conveyors of car manufacturers and to products for the aftermarket. It is enough to name just one number here: the company has over 2000 homologations for the original equipment, 700 of which are on the account of the flagship product - the P Zero model. The company does not hide that the main efforts of the Pirelli R&D department are aimed specifically at premium products, therefore 3.2% of the funds received from the total sales volume are invested in research and development. But Russia is a special market. Including from the point of view of the distribution of the share of products by seasonality. Last year, the company's turnover in Russia, excluding original equipment, amounted to 1.35 billion euros, with 60% accounted for by winter tyres... And when it comes to the winter line, Pirelli's marketers were right to go beyond premium models. Today, the "winter portfolio" of the Russian representative office of the company includes products of three price segments. In segment A it is studded ice model Zero and friction Ice Zero FR, the B segment includes the Formula Ice line, and the C segment - Amtel Nordmaster Evo tyres. Yes, given the new economic situation, the market is changing, and the interest of customers in certain price segments is changing. Pirelli takes this into account, but the course for leading positions in the premium segment still does not change.

Pirelli is constantly working to ensure that the winter segment of the company's products is not inferior in popularity to summer tyres.

NOT ONLY SALES

Pirelli's plans to work in Russia were not limited to a commercial presence: the long-term development program provided for the location of production here. Moreover, there was no talk of building new, from scratch, production sites - the possibility of acquiring existing specialized enterprises was considered. And at the end of 2011, the joint venture, which included Pirelli and the state corporation Rostec, bought out the Kirov Tyre Plant from the Sibur holding, and just a couple of months later Pirelli acquired the Voronezh Tyre Plant. And here I foresee some doubts of our readers: what kind of premium product can we talk about if it is produced in an old production facility? Indeed, the first tyre at the Voronezh plant was produced in December 1950. And now a couple more figures: the total investment of Pirelli in Russia exceeds 400 million euros, and more than 200 million was invested in the development of two plants. Today Voronezh Tyre Plant produces tyres in premium segment in standard sizes from 16 to 21 inches and, of course, this required a deep modernization of production: 73 million euros were invested in the development of production facilities alone. In January 2013, a new production line with a full technological cycle with a design capacity of 2.2 million tyres per year was launched here. At the same time, a new logistics center began operating, through which products are supplied to the CIS countries, the EU and Scandinavia. And this is already a new strategy - last year 26% of all Pirelli tyres produced in Russia were exported.

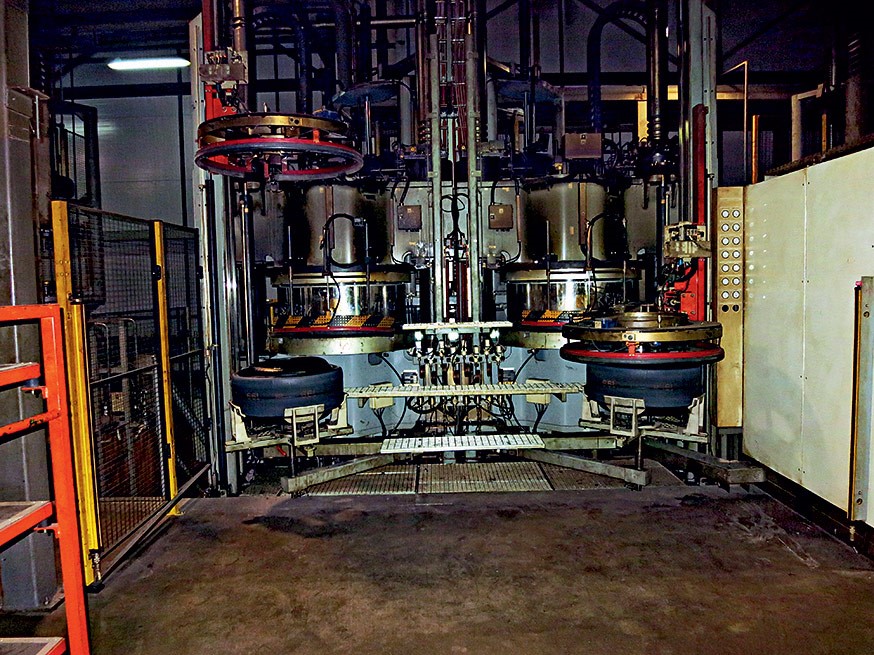

Tyre vulcanization workshop

At the same time, Pirelli is optimistic about expanding localization in terms of reducing imports of components required for production. So, in 2013, Pirelli and the state corporation Rostekhnologii acquired a new strategic partner - OJSC NK Rosneft. The goal of this alliance is joint research and development in the production of synthetic rubbers and related materials.

Today, Voronezh Tyre Plant supplies products for the EcoSport, Mondeo and Transit models only to the Ford assembly plant. And the employees of the plant consider one of their main achievements to be the zero level of defectiveness of products supplied to assembly lines. This is about the quality of products made in Russia.

Pirelli research laboratories are constantly working to improve technical parameters existing models. The release of fundamentally new options does not stop, striving to satisfy the growing market demand.

The company has 6 centers located in 6 different countries. The staff of these departments is about 2,000 highly qualified specialists. Each development, after a series of tests and adjustments, is embodied in the production process.

To describe the geographical scope of the Pirelli group of companies, an estimate of the volume of industrial operations is excellent, of which 85% is outside Italy, and 50% is created outside Europe. The points of sale of Pirelli products are scattered in more than 120 countries of the world.

An excellent example of the emergence of a Pirelli production in a new country can be seen on the example of the Italian expansion into Russia. Pirelli works closely with carmakers. There is a constant search for contracts for the supply of rubber for models produced from the conveyor. Pirelli tyre developers strive to create unique options for specific vehicle modifications. This allows you to maximally adapt the tyre to the needs of the car manufacturer and provide the buyer best conditions for driving. According to the final calculations, the holding acquired 2 powerful enterprises, quickly replenished them up to required level and launched the production of tyres, while saving impressive funds. And by 2015, the share of Pirelli tyres has grown several times. The company adjusts the range of products offered in accordance with market demand and the structure of the country's vehicle fleet. The creation of powerful industries, dotted across the region, allows you to monitor the dynamics of the market and quickly respond to its changes.

The presentation of the Q1 status certificate by the representatives of Ford to the factory workers

Aimone Di Savoia Aosta, CEO of Pirelli Tyres Russia LLC (right), receives a Q1 status certificate from a Ford representative

From the rubber mixing workshop, the product is sent to the production of rubber compounds of various formulations

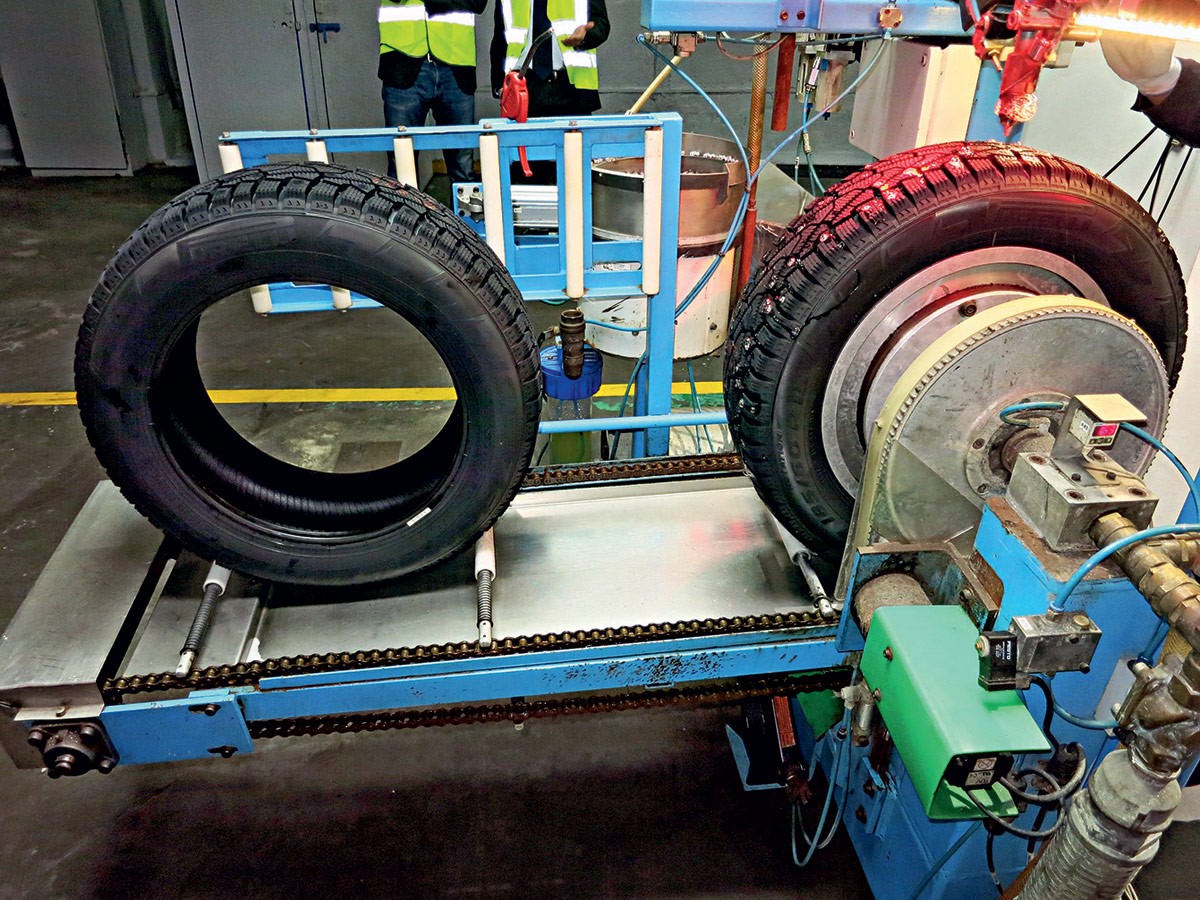

All Pirelli winter tyres are studded exclusively in the factory. This is the only way to guarantee high quality products.

Before going to the finished product warehouse, tyres undergo instrumental control. But it is preceded by mandatory visual control